Until when can you safely use your components?

Determining the remaining useful life of your assets

It goes without saying that you place high value on the sustainable use of your equipment and the components therein. Therefore, it is important to know when to replace them. For that, you first need answers to a number of questions. For example: To what extent has a component or piece of equipment been subject to wear or ageing? How long will it be safe for you to continue to use it? Should it be replaced when it reaches the end of its planned lifetime? You can find the answers to all these questions by determining the remaining lifetime of your assets. DEKRA is happy to do this for you and to give you insight into the condition of your components and/or equipment.

- Large-sized rubber components (for example from the OosterSchelde storm surge barrier)

- Steel rubber components from rail vehicle bogies

- (Aluminium) high voltage cables

- Insulated wiring

- Hydraulic hoses

- Guardrails along highways

- Rail brake rail seat

- Rail brake frame for hydraulics

- Bearings and plastic wheels from luggage transport systems

- Shock absorbers in rail vehicle bogies

The benefits of determining the remaining lifetime of assets

- You get the most out of your assets against minimal risks.

- You can use your assets sustainably and only replace them when necessary.

- You guarantee the safe use of your equipment.

- You reduce risks by ensuring that your assets are within requirements.

- By preventing the failure of your assets, you avoid the great expense their failure sometimes involves.

- You gain insights that allow you to optimise your maintenance approach.

- You can plan maintenance better.

- You may be able to reuse materials responsibly.

Determining the remaining lifetime of assets for the purpose of asset management

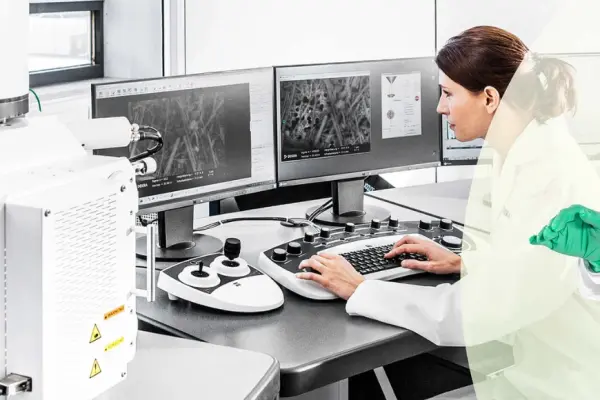

DEKRA’s approach

- the extent and cause of degradation (including cracks or crack initiation, wear, corrosion and ageing);

- the condition of the material; and

- the loads a component or construction must be able to withstand. For example, heat or moisture.

Remaining lifetime determination by DEKRA

Examples from the field

Why DEKRA?

Schedule a 1:1 session

2. Submit your unique case.

3. Get valuable insights on concrete follow-up steps.